BMZ Group to fund battery tech-related fellowship on impulse program

Since the program began, impulse has helped a raft of innovators commercialise their advancements in battery technology.

From powering electric vehicles and the next generation of consumer electronics to enabling renewable energy storage, batteries are at the heart of modern technology and the transition to a cleaner, more energy-efficient future energy grid, reducing our reliance on fossil fuels and accelerating the adoption of renewable energy sources.

Sanzhar Taizhan, founder and CEO of TaiSan and Emma Antonio, who aims to spin out of Imperial College London this Summer, are two recent impulse graduates pushing battery tech boundaries and bringing the chemistry to the next level.

They follow in the footsteps of impulse alumni, Jean de La Verpilliere, co-founder and CEO of Echion Technologies and Kieran O’Regan, co-founder and CGO of About:Energy.

Last November, Echion’s partner CBMM unveiled the world’s largest Niobium anode production facility dedicated to producing Echion’s ultra-fast charging XNO® active anode material technology. The new plant, located in Araxá, Brazil, is capable of producing 2,000 tons per year of XNO® – equivalent to 1 GWh of lithium-ion (Li-ion) cells. The facility enables Echion to mass-produce XNO® at scale to meet worldwide demand for the product.

London-based battery technology company, About:Energy has raised over £4 million to scale its hardware-integrated software solutions, enabling advanced digital twins for the automotive and industrial sectors. In October, About:Energy opened a 3,000 sq ft state-of-the-art battery testing facility in Southwark to provide critical data and insights for battery performance.

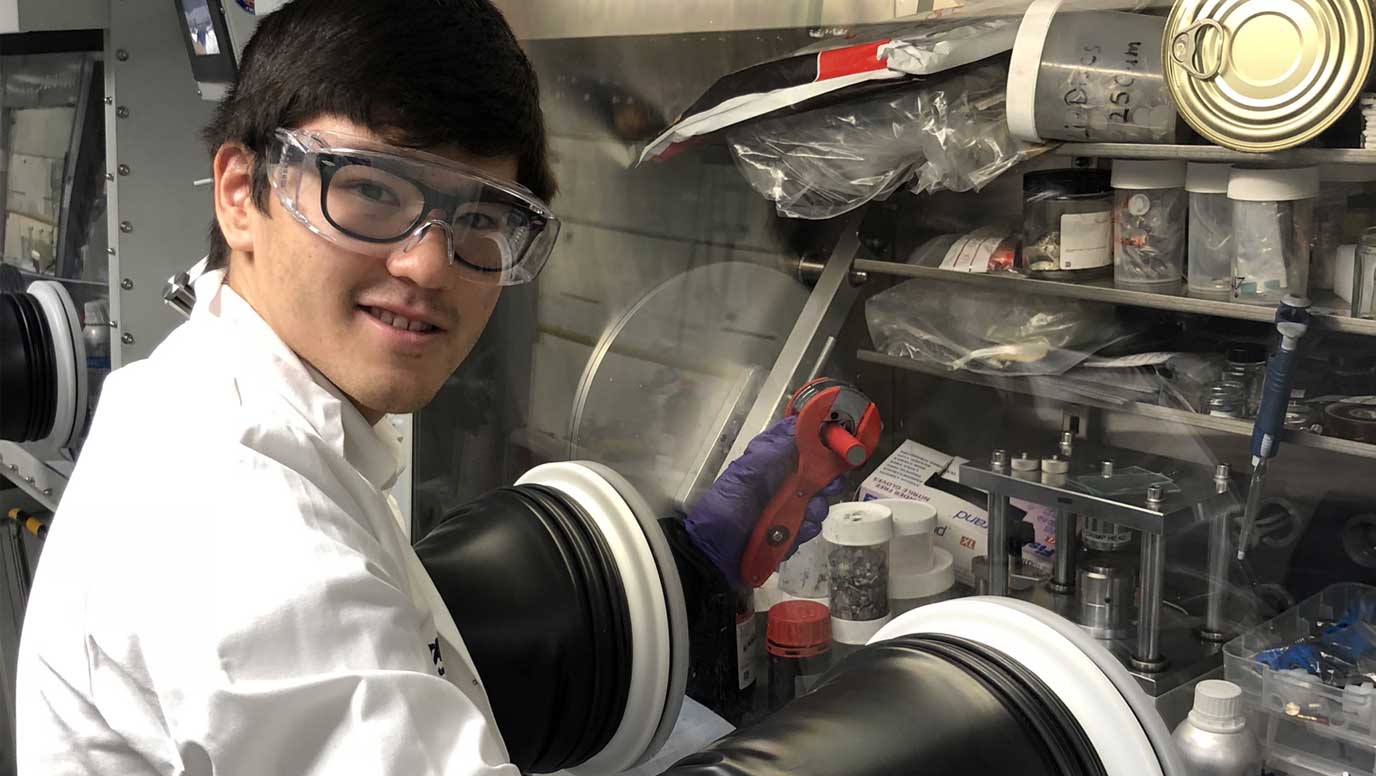

Sanzhar Taizhan – who was awarded an impulse fellowship, sponsored by automobile parts manufacturer, MAGNA International – is similarly progressing his quasi-solid state sodium technology for battery-powered electric vehicles (BEVs). TaiSan has developed a novel polymer electrolyte and anode material able to boost the energy density of sodium whilst keeping costs low.

Sanzhar says: “Sodium batteries are traditionally very heavy and big in size. We have developed a brand-new electrolyte material, and a first-of-its-kind quasi-solid-state sodium battery, which makes batteries considerably smaller and lighter, with best-in-class energy density, and offers significant cost, sustainability and safety benefits for the BEV industry.”

Last year, TaiSan received a “Best Growth Potential” award from the Department for Transport (DfT), as well as a £1.3m pre-seed fund raise (EIT InnoEnergy, TSP Ventures, Heartfelt VC and Exergon).

Now, with memorandums in place and prototypes being tested this year, TaiSan’s pioneering technology looks set to be a gamechanger for both the automotive and micromobility industries – providing reliable battery cells to address ‘range anxiety' amongst EV users, reduce charging times, and ultimately drive down overall costs.

Meanwhile, Emma Antonio, who only graduated from impulse last year, is using waste materials to make biomass-based ‘hard carbon’ battery materials for sodium-ion batteries.

Emma says: “Sodium-ion batteries are a more sustainable, affordable and energy-secure alternative to existing lithium-based technologies, as they can eliminate the need for critical minerals. Current battery supply chains are heavily dependent on a few key regions, creating vulnerabilities in energy security.

“In contrast, sodium-ion batteries - made from low cost, locally sourced, abundant materials - are positioned to play a leading role in a sustainable, equitable and resilient energy future. And as they can be manufactured using existing capabilities, they are rapidly gaining traction, especially in the stationary storage sector, to support wind and solar.

“In sodium-ion batteries we can replace the critical mineral graphite with hard carbon, which can be derived from a variety of sources, including biomass and plastic waste. We have developed a material that stores more charge, charges quickly and lasts longer.

“In the near term, like Echion Technologies, we are focused on commercialising the advanced material that we have developed. However, longer term our vision extends beyond a single component – we aim to pioneer a new sodium battery chemistry.”

The closing date for applications to impulse 2025 is March 3. The action-learning initiative – which runs from 29 April to 11 July 2025 – is designed to accelerate high-potential innovations into commercial propositions, guided by innovators and mentors from the Cambridge innovation cluster.

impulse is specifically designed for high-potential individuals (early-stage entrepreneurs, PhDs, postdocs, researchers) and organisations (engineers, managers, scientists of large corporations) across the different technology fields of Engineering, Physics, Biotechnology, Computer Science, Mathematics, Chemistry and Medicine.

impulse alumni include the founders of Riverlane, Abselion, Nu Quantum, Xampla, Echion Technologies, Wave Photonics, AllFocal Optics (formerly Lark Optics), Semarion, and About:Energy.

• To apply for the 2025 program visit – https://www.maxwell.cam.ac.uk/apply-impulse