$85bn market calls as Cambridge University battery babe Molyon raises $4.6m

Molyon has raised its maiden funding in a round co-led by IQ Capital and Plural. The money will kickstart manufacturing at a pilot facility in Cambridge through expansion of the core team including battery engineers, material scientists and operations staff. The team is currently vetting suitable sites.

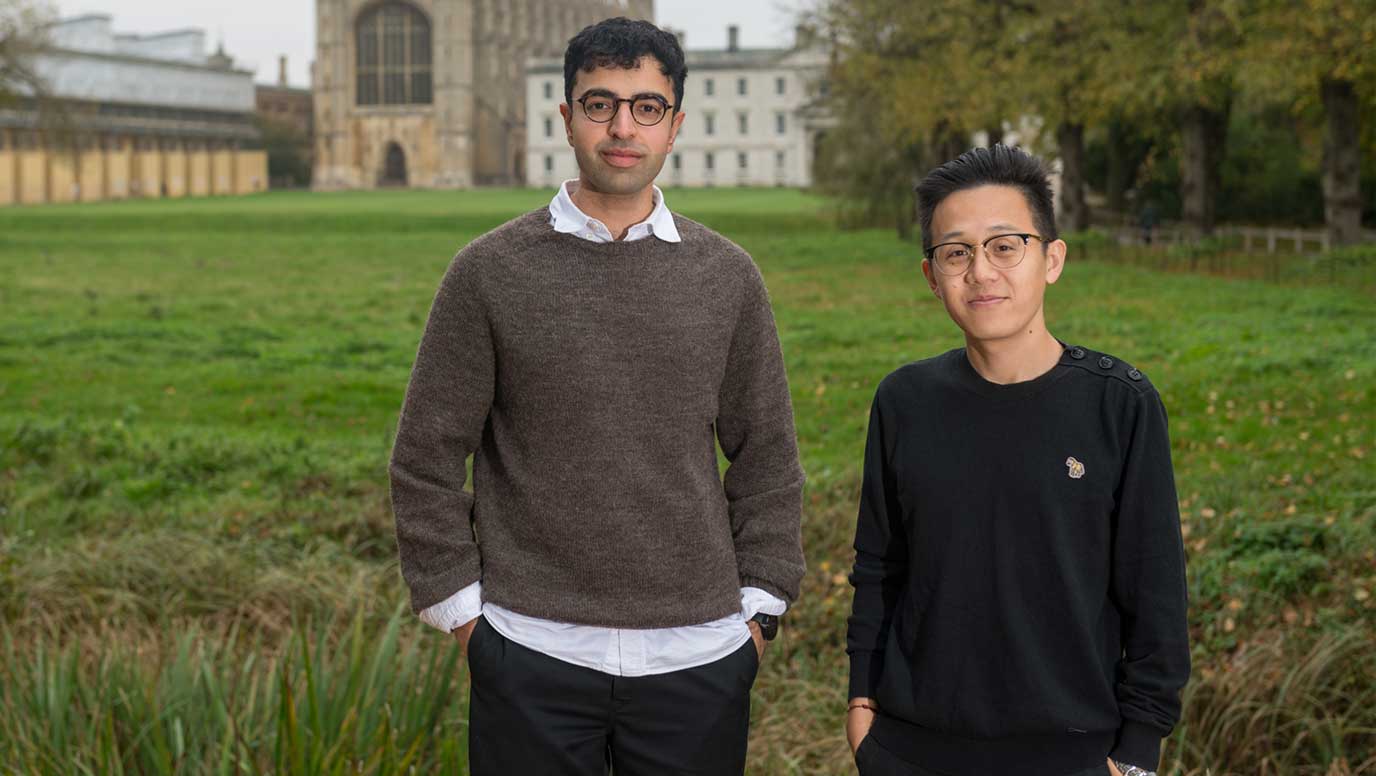

The company has emerged from 15 years of material science research in the Chhowalla Group at the University of Cambridge. Co-founders Dr Ismail Sami (CEO) and Dr Zhuangnan Li (CTO) met whilst studying under co-founder Professor Manish Chhowalla (Chief Scientific Officer), where they discovered and developed the high-performance cathode technology.

A fourth co-founder, Dr Sai Shivareddy (co-founder and CEO of fast-charging battery tech startup Nyobolt) is a commercial adviser to the company.

Molyon is specialising in high-energy-density lithium-sulfur (Li-S) batteries with improved performance, more earth-abundant materials and resilient supply chains. It says its nextgen batteries will double the energy density of current lithium-ion versions.

The rise in electrification to combat the climate crisis and eliminate fossil fuels in industries such as transportation means demand for batteries is higher than ever.

Lithium-ion (Li-ion) batteries, the current industry standard, are low energy density leading to heavy batteries with limited range and recharge capacity. Li-ion batteries also rely on critical materials, including nickel, manganese and cobalt that face supply chain issues.

As a result, there is a global push to discover higher-performance batteries, with resilient supply chains, to lay the foundation for an electrified world.

Lithium-sulfur (Li-S) batteries have significantly higher energy density than Li-ion and utilise readily available materials, including sulfur, the fifth most abundant element on Earth.

They have the potential to solve key issues including range anxiety in EVs. However, state-of-the-art Li-S batteries have yet to be commercialised because sulfur from the cathode dissolves into the electrolyte – causing the anode to corrode and the battery to fail after only a few cycles.

Founded earlier this year, Molyon has developed a cathode technology based on metallic molybdenum disulfide (MoS2) that allows sulfur to remain stable and provide high energy density over hundreds of cycles – revolutionising the Li-S battery field.

Since patenting the discovery, the team has demonstrated practical batteries with energy densities of 500 Wh per kg – approximately twice that of the typical Li-ion battery, showcasing the potential for Li-S batteries at such an early development stage.

Following the new funding, which builds upon recently awarded research grants from institutions including the University of Cambridge, Faraday Institution, Royal Academy of Engineering, Advanced Propulsion Centre, Sir Henry Royce Institute and the European Research Council, Molyon will expand the team and begin manufacturing at a pilot facility.

In the short term, this will enable the company to develop Li-S batteries for drones and robots, which will benefit from the lighter weight and improved range that Molyon’s batteries will provide.

Beyond this, Molyon’s technology could double the range for transportation applications, enabling it to tap into an $85 billion+ global market.

Dr Ismail Sami, co-founder and CEO of Molyon, said: “The promise of lithium-sulfur batteries has been envisaged for decades but until now it has not been possible to realise this potential because of the inherent chemistry challenges of working with sulfur.

“By utilising MoS2 we have achieved a groundbreaking milestone in battery technology innovation and are on track to bring this new battery chemistry to the market, creating batteries that will end range anxiety.

“We have an unrivalled founding team, which between us has years of commercial and research experience, along with insightful advisers and world-leading investors. Now we have the right backing to go forward and disrupt the industry for the better.”

Max Bautin, General Partner at IQ Capital, said: “Molyon have made a groundbreaking discovery in materials science to bring a step-change in battery energy density and unlock a massive market.

“We’ve been so impressed with the passion and experience of the Molyon team, as well as the maturity level at which they have already demonstrated the potential of their technology. We’re delighted to be supporting Molyon at this exciting point in their venture as they scale to their first pilot facility and beyond.”

Cambridge has already spawned battery stars Nyobolt and Echion Technologies. Nyobolt is blazing a trail with high power, ultrafast charging battery technologies. Its cells can be fully charged from 0 per cent to 100 per cent state of charge in as little as five minutes, with minimal degradation, while demonstrating superior cycle life far beyond what can be achieved in today’s lithium-ion cells. Nyobolt is in talks with eight vehicle heavyweights about adopting its technology in high performance electric vehicles.

Echion Technologies recently raised £29 million in a Series B round led by specialist battery and energy storage technology investor Volta Energy Technologies with participation from existing investors CBMM, BGF and Cambridge Enterprise Ventures.

Echion’s XNO® niobium-based anode material enables lithium-ion (Li-ion) batteries to safely fast charge in less than 10 minutes, maintain high energy densities even at extreme temperatures, and deliver high power across a cycle life of more than 10,000 cycles. This month, Echion partner CBMM unveiled the world’s largest Niobium anode production facility dedicated to producing Echion’s XNO® technology.

The new plant, located in Araxá, Brazil, is capable of producing 2,000 tons per year of XNO® – equivalent to 1 GWh of lithium-ion (Li-ion) cells. The facility enables Echion to mass-produce XNO® at scale to meet worldwide demand for the product.

Another University of Cambridge spinout, Illumion, is revolutionising how we measure energy storage in operating batteries. By providing a new, simple and lab-based measurement platform it enables researchers to visualise energy storage processes in real time, at sub-micrometer scales, and in realistic sample environments. The Illumion board is packed with specialists in the field – including Professor Clare Grey of Nyobolt as a co-founder.