42 Technology and partners unveil new AI-powered pharma line clearance solution

The partners have pooled their tech expertise and application knowledge to develop a lower cost, flexible, and scalable alternative to existing AI-powered automated technologies.

Most dedicated systems designed to automate line clearance processes are too expensive for widespread use because of their high hardware costs, complex integration, and the need for extensive training on production lines.

The new approach, which has been developed with inputs from some of the world’s leading pharmaceutical manufacturers, addresses these challenges by using a fully autonomous, deep-learning AI platform.

Unlike conventional alternatives, the inspection system is designed to enable in-process learning without the need for lengthy setup and training routines on live production lines.

Line clearance checks are critical in pharmaceutical manufacturing to ensure that all materials, products, labels and records from a previous batch have been completely removed before starting the next one.

The process involves multiple manual inspections, often taking up to one hour between batches, which significantly impacts production efficiency, especially as the industry shifts towards personalised medicine and smaller batch sizes. Industry experts estimate up to 85 per cent time savings with automated line clearance versus current manual checks.

42T has designed and built a technology demonstrator to showcase this new AI-driven system in action. It was being launched at this week’s Embedded World event in Nuremberg, Germany at the Synaptics booth. It will also feature at several other major industry and customer events throughout 2025.

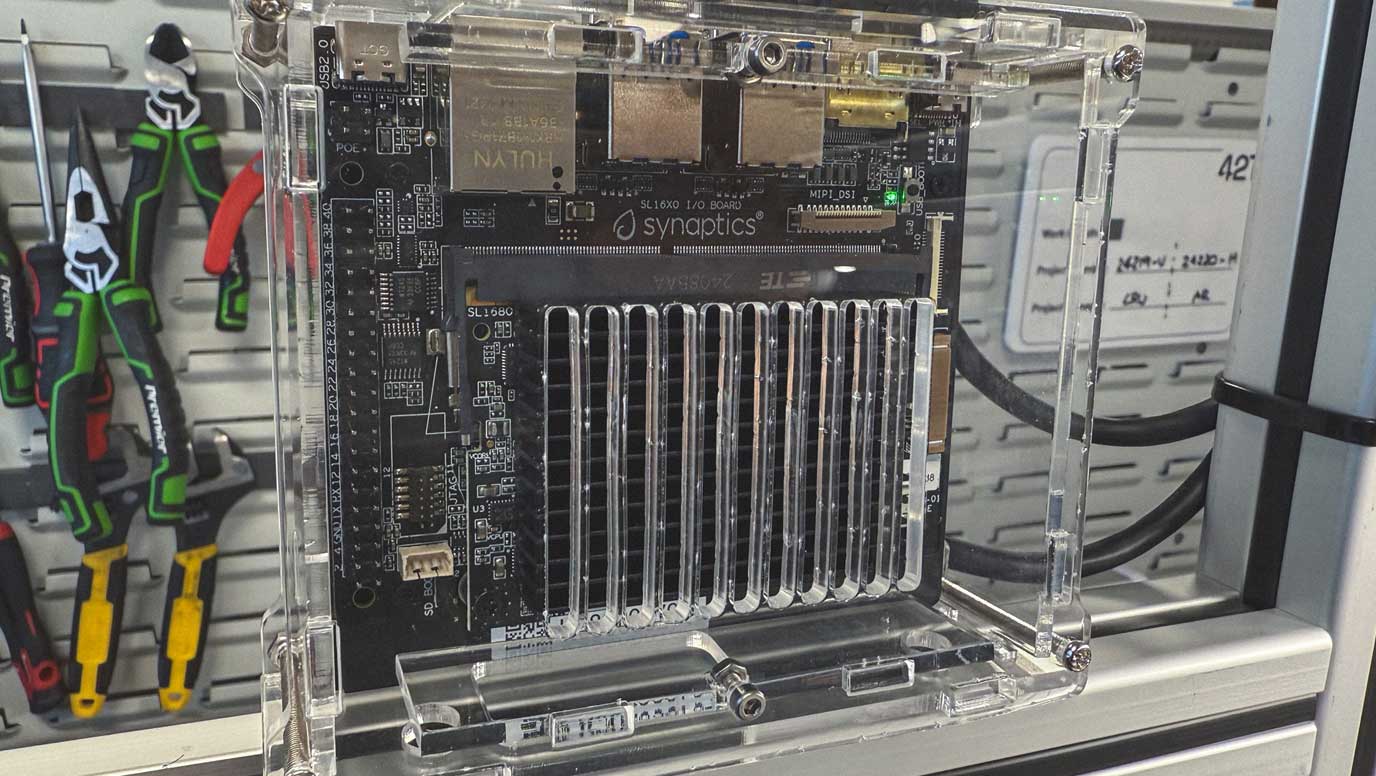

The new AI-powered approach combines Balluff’s high-performance image acquisition system with Arcturus’s deep-learning models and the Synaptics AstraTM SL1680 edge AI processor. The Astra SL-Series won Best in Show at last year’s Embedded World event for its exceptional AI capabilities, low power consumption and cost efficiency.

42T and its partners have worked together to develop their breakthrough approach to target the cost and performance requirements of the pharmaceutical sector but it could also be used in other regulated industries such as medical devices, and food and beverage.

The system uses fixed position cameras at key locations for monitoring, and is flexible enough to accommodate ‘pan and tilt’ cameras to scan different production areas depending on the application.

• PHOTOGRAPH: The Synaptics Astra SL1680 edge AI processor is ideal for pharmaceutical manufacturers looking to integrate automated line clearance across multiple production lines as it enables faster, more adaptive decision-making. Credit – 42 Technology.